Introduction to ViP AMOLED Features

Author: Release Time: 2023-12-18

Visionox intelligent Pixelation (ViP), the world's first fine metal-free mask (FMM) RGB self-aligned pixelization technology, was launched by Visionox. This technology can significantly improve the performance of AMOLED products, increase the effective light-emitting area (aperture ratio) of AMOLED products from the traditional 29% to 69%*, and push the pixel density to over 1,700 ppi*. When combined with Visionox's Tandem stacked devices, ViP could result in six times the lifespan, or four times the brightness, of standard FMM AMOLEDs.

ViP technology fundamentally solves FMM-related problems in the existing manufacturing process of FMM AMOLEDs, and breaks through the limitations on performance, cost and defects of products. Consequently, it will drive the display industry into a new area of AMOLED+.

Technical Principle of ViP

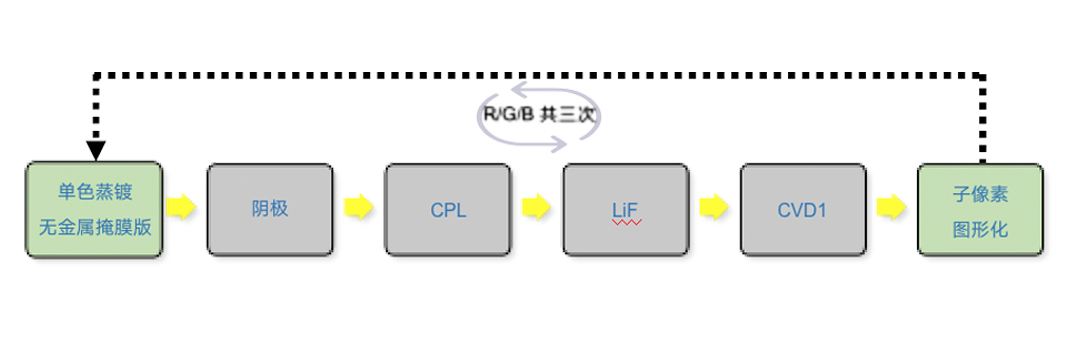

ViP technology does not require the use of FMM evaporation. The existing AMOLED technology and process can be used for TFT control backplanes. After anode preparation, the pixel defining layer (PDL) shows stepwise differentiation, forming the unique isolation column structure of ViP AMOLEDs. Then it is patterned on the substrate using the whole surface evaporation and photolithography process for the preparation of pixels.

First of all, the whole surface is evaporated to deposit all emissive layers (EL) and functional layers of OLEDs that emit the first color, and then encapsulated with a thin film (the first inorganic layer). Next, unwanted areas of the substrate are selectively removed by gluing, exposure, development, etching and peeling. This is a critical step to eliminate the fine metal mask and finish patterning the first color. Subsequently, the process above is repeated twice until full-color patterning is done for RGB (three-primary colors).

Technical Advantages of ViP

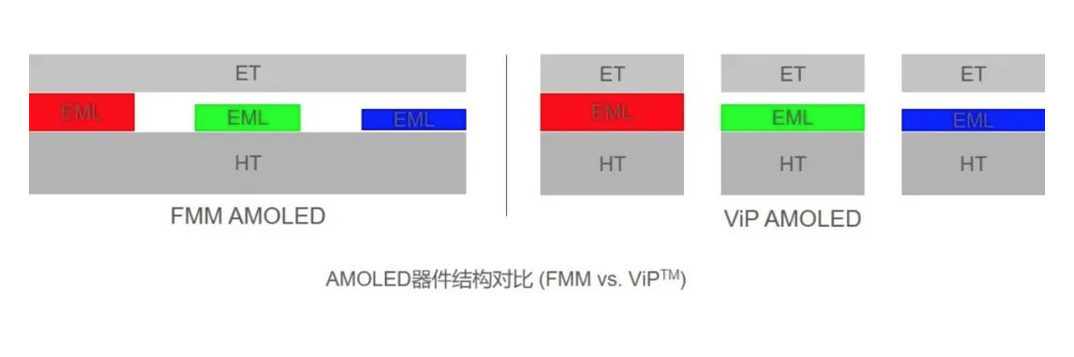

ViP technology has broken through the bottlenecks caused by FMM, such as large precision limitation, low material utilization, high mold opening cost, long development and production cycle, and simple panelization. In a ViP AMOLED device, RGB sub-pixels are photoetched, enabling an independent sub-pixel structure. For each sub-pixel, the EL device structure can be designed independently and its performance adjusted independently, which is the fundamental reason why ViP technology offers many performance advantages. However, in the FMM AMOLED technology route, because each common layer in the EL device serves RGB sub-pixels at the same time, it is impossible to independently debug or optimize sub-pixel devices, which limits the performance of the EL devices.

Since ViP technology features FMM-free and high-precision production of independent OLED sub-pixels, better product performance, full-size applications, and more flexible production and delivery are realized.

Higher Brightness and Longer Lifespan

ViP technology adopts photolithography-based pixelating processes and special PDL design, which allows for narrower PDL opening spacing. It can increase the effective light-emitting area (aperture ratio) of AMOLEDs from the traditional 29% to 69%, leading to a longer lifespan. When combined with Tandem stacked devices, ViP could result in six times the lifespan, or four times the brightness, of standard FMM AMOLEDs.

Better Image Quality

· Small JNCD

For each RGB sub-pixel device, its film thickness can be customized individually, enabling more flexible optical performance debugging of the EL devices. At all viewing angles below 75°, the just noticeable color difference (JNCD) of ViP AMOLEDs can decrease to less than 1.0.

DCI-P3 Color Gamut > 100% at Low Grayscales

The isolation column structure of ViP AMOLEDs cuts off the connection of common layers between sub-pixels, thus avoiding crosstalk between pixels. At low grayscales (low brightness), ViP AMOLEDs can keep DCI-P3 color gamut over 100%, the same as at high grayscales.

Better Brightness Uniformity and Lower Power Consumption

ViP technology allows for a metal mesh structure formed by the isolation column structure around each pixel, in which VSS current is transmitted with very small resistance. This can reduce in-plane VSS IR-Drop in the display area, and realize higher brightness uniformity and lower power consumption since power consumption is almost unaffected by panel size. For example, ViP technology can reduce laptops’ power consumption by more than 38%.

Higher PPI

Without FMM, ViP AMOLEDs still use Real RGB pixel arrangement at high ppi. ViP technology can push pixel density to over 1,700 ppi, so that OLED applications can be extended to near-to-eye display devices such as AR/VR. Meanwhile, ViP AMOLEDs are greatly improved in terms of high brightness, low power consumption and long lifespan. They can take into account medium- and large-sized display requirements for performance and power consumption, and achieve full coverage of full-size application fields.

Higher Reliability

With individual micron-scale sub-pixel packaging, ViP AMOLEDs are better isolated from water and oxygen, which effectively inhibits the generation of diffusible dark spots and improves product reliability.

Higher Transmittance

Because the ViP-based EL device is patterned in a photolithography process, useless films (e.g. cathode and EL) can be removed in high-transmittance areas, which greatly improves the transmittance of transparent AMOLEDs.

More Flexible Production and Delivery

ViP technology solves the pain points of FMM, such as high design cost, long lead time, and high minimum order quantity (MOQ). Moreover, it generates new advantages in mass production, including lowered MOQ, improved panelization, and customized free-form display.